- Home

- ACCUWAY - CNC Machines

- CAR s.r.l. - Honing Machine

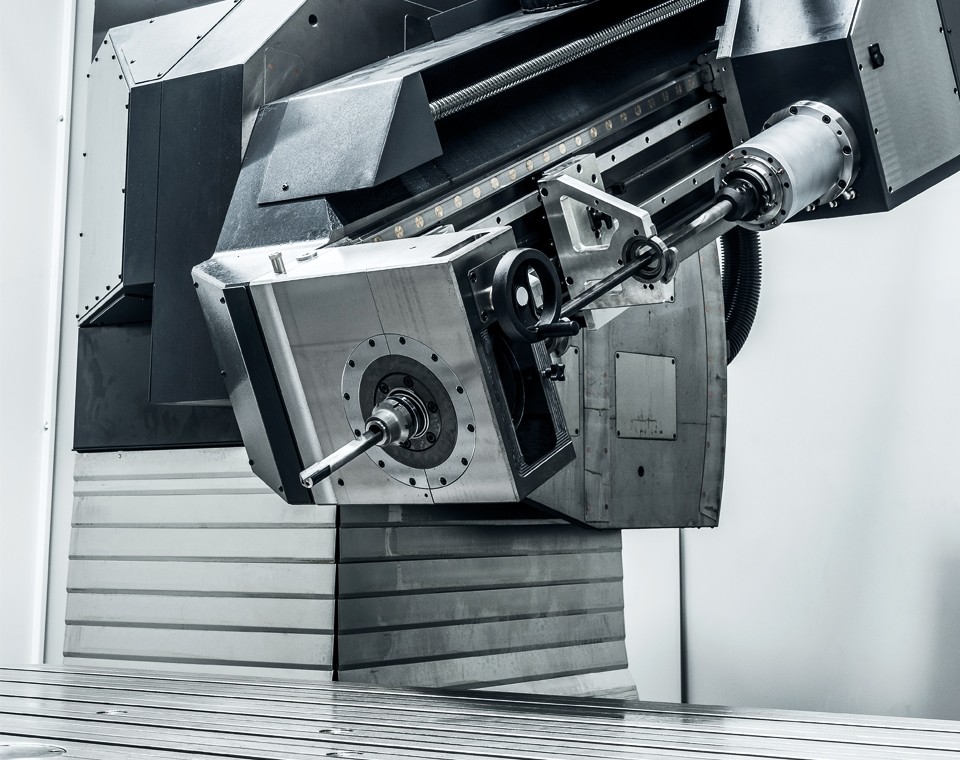

- CHETO - CNC Deep Hole Drilling with Milling

- CMS Metal - Deburring-finishing Machine

- CMS Tecnocut - Waterjet Technology

- Compact Vertical Machining Center

- Deep Hole Drilling Machine

- exeron - HSC - High Speed Milling Center

- JOHNFORD - CNC Machines

- KINGSTON - CNC Oil Country Lathe

- KINGSTON - Engine Lathe

- Straightener

- TOS VARNSDORF - CNC Borer

- Trepan Drilling [ Coring ] Machine

- unisign - Machining Centre

- WEINGÄRTNER® MASCHINENBAU - Complete Machining Solutions

WHY CHOOSE CHETO :

- Innovative concept for mold makers and service companies

- Deep hole drilling, standard drilling, milling, tapping, boring in a single machine

- Eliminates setup operations in mold manufacturing

- Excellent quality/price ratio

- Reduction of time and costs

- Embedded drilling and machining processes, minimizing human errors

- Brand of excellence, internationally recognized in the mold industry

- CHETO machines represent an excellent investment for their multitasking features

ADVANTAGES

1st 60% reduction in drilling time

2nd 40% reduction in setup time

3rd 20% reduction in mold machining time

IMPORTANT FEATURES

→ Rapid Tool changing systems to change between deep hole drilling and milling processes effectively

→ Customized structure to increase milling capacity (chips removal rate)

→ Active control software dedicated to deep hole drilling, tapping and milling

→ Ability to, in a single click, translate and rotate coordinates

→ Latest generation of numerical controls, digital servo-drives, linear slides and high-precision roller guides

→ Filtering and cooling the cutting fluid

→ Pressure and flow adjustment to meet the tools requirements

→ Deep hole drilling with gun-drills at high pressure

→ Smart and online control system with remote access

→ Rapid and precise machining

→ Self-compensation of the machine’s dimensional parameters in relations to operating conditions,

namely : temperature, humidity, vibration, etc.

→ Optimized life cycle, safety and energy efficiency

→ Easy reconfiguration and adaptation to new production/manufacturing realities

→ User-friendly, safety and environmental efficiency